Sweco Fab/PT&P also manufactures:

- Basket Strainers

- Line Strainers

- Tee Type Strainers

- Perforated Plates

hbspt.forms.create({

portalId: “88145”,

formId: “4155c206-adb0-4aeb-8732-642070c4c83a”

});

Sweco Fab, Inc. manufactures conical strainers per ANSI B31.3 and other codes. Line strainers, tee type strainers and perforated plates are also available.

Sweco Fab/PT&P also manufactures:

hbspt.forms.create({

portalId: “88145”,

formId: “4155c206-adb0-4aeb-8732-642070c4c83a”

});

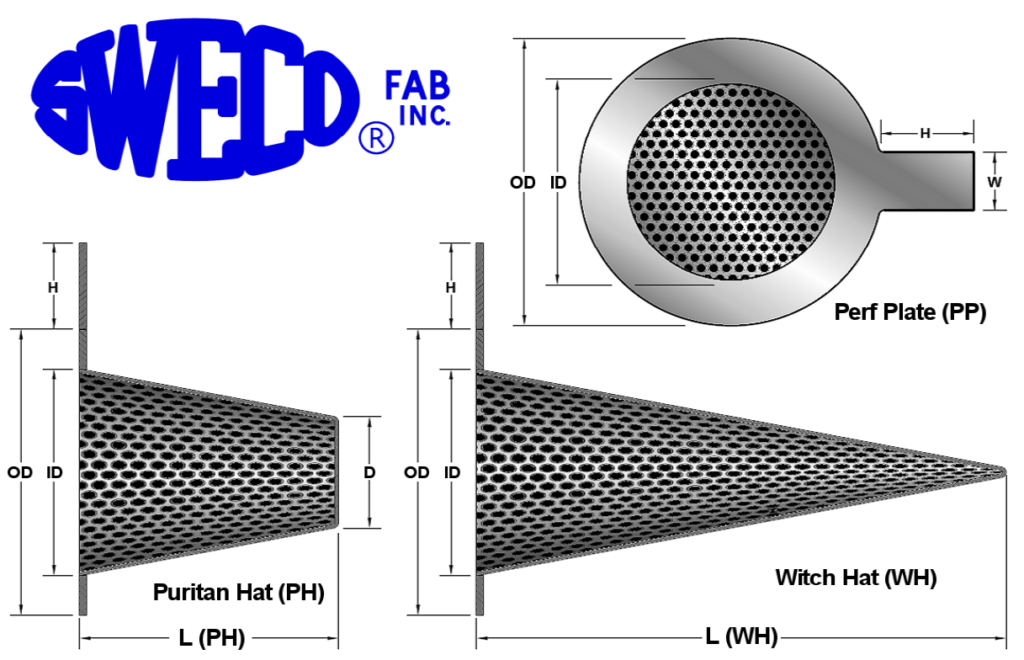

Dimensions are in Inches

Standard perf is 1/8” opening on 3/16” centers

NOTE: Standard Handle and Ring Thickness is 1/8” (11 GA)

NOTE: Standard Handle Width (W) is 1”

NOTE: Standard Handle Length (H) is 3 1/2”

| NPS | OD (ALL) | ID (ALL) | L (WH) | L (PH) | D | ||||||||||

| 150 | 300 | 600 | 900 | 1500 | 150/300 | 600/900 | 1500 | 150% | 200% | 300% | 150% | 200% | 300% | ||

| 1 1/2 | 3 1/4 | 3 5/8 | 3 5/8 | 3 3/4 | 3 3/4 | 1 3/8 | 1 3/8 | 1 1/8 | 3 | 4 | 5 3/4 | 2 | 2 1/2 | 3 1/2 | 1 |

| 2 | 4 | 4 1/4 | 4 1/4 | 5 1/2 | 5 1/2 | 1 7/8 | 1 3/4 | 1 1/2 | 4 | 5 1/4 | 7 1/2 | 2 3/4 | 3 1/2 | 4 3/4 | 1 1/4 |

| 2 1/2 | 4 3/4 | 5 | 5 | 6 3/8 | 6 3/8 | 2 1/4 | 2 1/4 | 2 | 4 3/4 | 6 | 9 | 3 | 4 | 5 3/4 | 1 1/2 |

| 3 | 5 1/4 | 5 3/4 | 5 3/4 | 6 1/2 | 6 3/4 | 2 7/8 | 2 3/4 | 2 3/8 | 5 3/4 | 7 3/4 | 11 1/4 | 3 3/4 | 4 3/4 | 7 | 2 |

| 3 1/2 | 6 1/4 | 6 3/8 | 6 1/4 | | | 3 3/8 | 3 3/8 | | 6 3/4 | 8 3/4 | 13 1/4 | 4 1/4 | 5 3/4 | 8 1/4 | 2 1/4 |

| 4 | 6 3/4 | 7 | 7 1/2 | 8 | 8 1/8 | 3 7/8 | 3 5/8 | 3 1/4 | 7 1/2 | 10 | 15 | 5 | 6.25 | 9 1/4 | 2 5/8 |

| 5 | 7 5/8 | 8 3/8 | 9 3/8 | 9 5/8 | 9 7/8 | 4 7/8 | 4 3/8 | 3 7/8 | 9 1/2 | 12 1/2 | 18 3/4 | 6 | 7 3/4 | 11 1/2 | 3 3/8 |

| 6 | 8 5/8 | 9 3/4 | 10 3/8 | 11 1/4 | 11 | 5 7/8 | 5 1/4 | 4 3/4 | 11 1/4 | 15 | 22 1/2 | 7 | 9 1/4 | 13 3/4 | 4 |

| 8 | 10 7/8 | 12 | 12 1/2 | 14 | | 7 5/8 | 6 7/8 | | 14 1/4 | 19 1/4 | 29 | 8 3/4 | 11 1/2 | 17 1/4 | 5 1/2 |

| 10 | 13 1/4 | 14 1/8 | 15 5/8 | 17 | | 9 3/4 | 8 3/4 | | 18 1/4 | 24 1/2 | 36 3/4 | 11 1/4 | 14 3/4 | 21 3/4 | 7 |

| 12 | 16 | 16 1/2 | 17 7/8 | 19 1/2 | | 11 3/4 | 10 1/2 | | 21 3/4 | 29 1/4 | 44 | 13 1/4 | 17 1/2 | 26 | 8 1/2 |

| 14 | 17 1/2 | 19 | 19 1/4 | 20 3/8 | | 13 | 11 1/2 | | 24 | 32 1/2 | 49 | 14 1/2 | 19 1/4 | 28 3/4 | 9 1/2 |

| 16 | 20 1/8 | 21 1/8 | 22 1/8 | 22 1/2 | | 14 3/4 | 13 1/4 | | 27 3/4 | 37 | 56 | 16 3/4 | 22 | 33 | 11 |

| 18 | 21 1/2 | 23 3/8 | 24 | 25 | | 16 3/4 | 15 | | 31 1/4 | 42 | 64 | 18 3/4 | 25 | 37 | 12 1/2 |

| 20 | 23 3/4 | 25 5/8 | 26 3/4 | 27 3/8 | | 18 3/4 | 16 3/4 | | 34 3/4 | 47 | 71 | 21 | 27 3/4 | 41 | 14 |

| 24 | 28 1/8 | 30 3/8 | 31 | 32 7/8 | | 22 3/8 | 20 1/8 | | 42 | 57 | 86 | 25 1/4 | 33 1/2 | 50 | 17 |

I. CASTING SPECIFICATIONS

STP standards casing designs are made using the following material specifications :

• Pipe : SA 106 B

• Flanges : SA 105

• Studs : SA-193 B 7

• Nuts : SA-194 – 2H

• Cplgs : SA-105

• Caps : SA-234 – WPB

• Gasket : 1/16″ Non-asbestos

• Heads : SA-516 Gr 70 2:1 Ellip

Special alloy materials as per ASME sec.2 are available, as well as any ANSF code specified. Custom supports using our ring design or lug supports are also available for our client’s needs. Our computer stress analysis programs and flow rate programs assure our clients of uniform and accurate designs on all PTP/SwecoFab strainers.

II. WIRE CLOTH SPECIFICATIONS

Materials:

Perforated metal

14 ga. – 1/8″ dia. Holes on 3/16″ centers, 33 holes per sq. inc., using carbon steel, 304SS, 304 L SS, 316SS, 316L SS, monel or nickel. Special metals available upon request. 11 ga. Is also available.

Wire cloth : carbon steel, 304SS 316SS, brass, monel.

Basket open area to inlet pipe cross-sectional flow area based on perforated 1/8″ diameter holes on 3/16″ centers, 33 perforations per square inch (40% effective open area).

Wire Cloth Data

| Wire Mesh (No.) | Wire Diam. (Inch) | Percent of Open Area % | Width Opening (inch) |

| 4X4 | 0.063 | 56.6 | 0.187 |

| 20X20 | 0.016 | 46.2 | 0.034 |

| 30X30 | 0.013 | 37.1 | 0.0203 |

| 40X40 | 0.01 | 36 | 0.015 |

| 60X60 | 0.0075 | 30.5 | 0.0092 |

| 80X80 | 0.0055 | 31.4 | 0.007 |

| 100X100 | 0.0045 | 30.3 | 0.0055 |

III. ORDERING INSTRUCTIONS

Please provide for our sales representatives the following minimum information :

1. TYPE

2. FLOW RATE ( liquid, gmp, density ); ( vapor/gas, lbs./hr., mol. wt . )

3. DESIGN PRES., psig; temp., oF

4. STRAINER SIZE

5. PIPE LINE SIZE, flange rating or weld ends.

6. WIRE CLOTH SIZE AND REQUIRED MATERIALS

7. CASTING MATERIAL; standard or custom.

8. SUPPORT; lugs, legs, ring or none

9. CODE COMPLIANCE, ANSI B31.–

10. SPARE PARTS; baskets, gaskets

IV. CODE COMPLIANCE

Strainers are designed in accordance with ASME B 31.3 pressure piping code latest editions. General design criteria has incorporated the innovation that all baskets are interchangeable for like nozzle size regardless of ANSI rating. For other ANSI rating, ASME SEC VIII D[V], and larger size, contact . engineering office, Houston, Texas.

| Down-Flow (without blowdown) | |||||||

|

|||||||

| Horizontal or Vertical (with blowdown) | |||||||

|

|||||||

| Pipe Size | A | B | C | D | E | F | ||||||||||||||||

| 150 | 300 | 600 | 900 | 1500 | 150 | 300 | 600 | 900 | 1500 | 150 | 300 | 600 | 900 | 1500 | 150 | 300 | 600 | 900 | 1500 | |||

| 2 | 2 1/2 | 10 | 10 1/2 | 11 1/4 | 13 1/2 | 13 1/2 | 5 3/4 | 6 1/8 | 6 7/8 | 8 1/2 | 8 1/2 | 5 | 5 1/4 | 5 5/8 | 9 1/4 | 9 1/4 | 10 3/4 | 11 3/8 | 12 1/2 | 15 1/4 | 15 1/4 | 1/4 |

| 2 1/2 | 3 | 11 1/2 | 12 | 12 1/2 | 14 3/4 | 14 3/4 | 6 5/8 | 7 | 7 3/4 | 9 1/4 | 9 1/4 | 5 3/4 | 6 | 6 3/8 | 10 3/8 | 10 3/8 | 12 3/8 | 13 | 13 7/8 | 16 5/8 | 16 5/8 | 1/4 |

| 3 | 3 3/8 | 12 1/4 | 13 | 13 3/4 | 15 1/4 | 16 1/2 | 7 1/16 | 7 5/8 | 8 3/8 | 9 3/8 | 10 3/8 | 6 1/8 | 6 1/2 | 6 7/8 | 11 | 11 5/8 | 13 3/16 | 14 1/8 | 15 1/4 | 17 | 18 5/8 | 1/4 |

| 4 | 4 1/8 | 14 1/4 | 15 | 16 3/4 | 17 3/4 | 18 1/2 | 8 1/16 | 8 3/4 | 10 1/8 | 10 7/8 | 11 5/8 | 7 1/8 | 7 1/2 | 8 3/8 | 13 | 13 3/8 | 15 3/16 | 16 1/4 | 18 1/2 | 19 | 20 7/8 | 1/4 |

| 5 | 4 7/8 | 16 3/4 | 17 1/2 | 19 1/4 | 20 1/4 | 22 1/2 | 9 5/16 | 10 1/8 | 11 5/8 | 12 3/8 | 14 3/8 | 8 3/8 | 8 3/4 | 9 5/8 | 15 | 16 1/8 | 17 11/16 | 18 7/8 | 21 1/4 | 22 1/2 | 25 5/8 | 3/8 |

| 6 | 5 5/8 | 18 1/4 | 19 | 21 | 22 3/4 | 25 1/4 | 10 1/8 | 10 15/16 | 12 5/8 | 13 13/16 | 16 1/8 | 9 1/8 | 9 1/2 | 10 1/2 | 17 | 18 1/4 | 19 1/4 | 20 7/16 | 23 1/8 | 25 3/16 | 28 3/4 | 3/8 |

| 8 | 7 | 22 | 22 3/4 | 25 | 27 1/4 | 31 1/4 | 12 1/8 | 13 | 14 15/16 | 16 3/8 | 19 1/2 | 11 | 11 3/8 | 12 1/2 | 20 5/8 | 22 5/8 | 23 1/8 | 24 3/8 | 27 7/16 | 30 | 35 1/8 | 3/8 |

| 10 | 8 1/2 | 25 | 26 1/4 | 29 1/2 | 32 | 13 11/16 | 15 | 17 1/2 | 19 | 12 1/2 | 13 1/8 | 14 3/4 | 24 1/2 | 26 3/16 | 28 3/8 | 32 1/4 | 25 | 3/8 | ||||

| 12 | 10 | 29 | 30 1/4 | 32 3/4 | 36 1/4 | 15 3/4 | 17 1/8 | 19 1/4 | 21 1/2 | 14 1/2 | 15 1/8 | 16 3/8 | 28 1/8 | 30 1/4 | 32 1/4 | 35 5/8 | 39 5/8 | 3/8 | ||||

| 14 | 11 | 32 | 33 1/4 | 35 1/2 | 17 3/8 | 18 3/4 | 20 3/4 | 16 | 16 5/8 | 17 3/4 | 33 3/8 | 35 3/8 | 38 1/2 | 1/2 | ||||||||

| 16 | 12 | 34 | 35 1/2 | 38 1/2 | 18 7/16 | 20 | 22 1/2 | 16 | 16 5/8 | 17 3/4 | 33 3/8 | 35 3/8 | 38 1/2 | 1/2 | ||||||||

| 18 | 13 1/2 | 38 | 39 1/2 | 42 | 20 9/16 | 22 1/8 | 24 1/2 | 19 | 19 3/4 | 21 | 39 9/16 | 41 7/8 | 45 1/2 | 1/2 | ||||||||

| 20 | 15 | 41 3/8 | 42 3/4 | 45 1/2 | 22 3/8 | 23 7/8 | 26 1/2 | 20 11/16 | 21 3/8 | 22 3/4 | 43 1/16 | 45 1/4 | 49 1/4 | 1/2 | ||||||||

| 24 | 17 | 46 | 47 1/4 | 50 1/2 | 24 7/8 | 26 3/8 | 29 1/2 | 23 | 23 5/8 | 25 1/4 | 47 7/8 | 50 | 54 3/4 | 1/2 | ||||||||

|

|||||||||||||||||||||

150 PSIG

| Sizes, Dimensions and Weights | ||||||||||||||||

| Nominal Line Size (in.) | Nozzle Size (in.) | Vessel Size (in.) | Basket Size | A (in.) | B (in.) | C (in.) | D (in.) | Wall Thickness | Pads Req'd | Drian Ring Thickness | Ratio of Inlet ID Area to Basket Open Area | Nominal Line Size (in.) | ||||

| Diam. (in.) | Avg. Ht (in.) | Nozzle (in.) | Vessel (in.) | Size (in.) | Support (in.) | Basket (in.) | ||||||||||

| 2 | 2.375 | 8.625 | 5 | 5 1/2 | 9 | 18 1/2 | 17 | 9 1/2 | 0.218 | 0.322 | No | 3/4 | 1/4 | 1/4 | 1000% | 2 |

| 3 | 3.5 | 8.625 | 5 | 5 1/2 | 9 | 18 1/2 | 19 | 9 1/2 | 0.216 | 0.322 | No | 3/4 | 1/4 | 1/4 | 500% | 3 |

| 4 | 4.5 | 10.75 | 6 | 8 | 11 | 24 | 21 | 13 | 0.237 | 0.365 | No | 3/4 | 1/4 | 1/4 | 500% | 4 |

| 6 | 6.625 | 12.75 | 8 | 10 | 12 3/8 | 27 7/8 | 24 | 15 1/2 | 0.28 | 0.375 | No | 3/4 | 1/4 | 1/4 | 400% | 6 |

| 8 | 8.625 | 16 | 10 | 13 | 15 | 35 | 28 | 20 | 0.322 | 0.375 | No | 1 | 1/4 | 1/4 | 350% | 8 |

| 10 | 10.75 | 18 | 12 | 16 | 17 3/8 | 40 7/8 | 31 1/2 | 23 1/2 | 0.365 | 0.375 | No | 1 | 1/4 | 1/4 | 350% | 10 |

| 12 | 12.75 | 20 | 14 | 19 | 19 5/8 | 46 5/8 | 34 | 27 | 0.375 | 0.375 | No | 2 | 1/4 | 1/4 | 350% | 12 |

| 16 | 16 | 24 | 18 | 27 | 22 | 57 1/2 | 40 1/2 | 35 1/2 | 0.375 | 0.375 | No | 2 | 1/4 | 1/4 | 350% | 16 |

| 18 | 18 | 30 | 20 | 28 | 24 | 62 | 48 | 38 | 0.5 | 0.5 | No | 2 | 1/4 | 1/4 | 300% | 18 |

300 PSIG

| Sizes, Dimensions and Weights | ||||||||||||||||

| Nominal Line Size (in.) | Nozzle Size (in.) | Vessel Size (in.) | Basket Size | A (in.) | B (in.) | C (in.) | D (in.) | Wall Thickness | Pads Req'd | Drian Ring Thickness | Ratio of Inlet ID Area to Basket Open Area | Nominal Line Size (in.) | ||||

| Diam. (in.) | Avg. Ht (in.) | Nozzle (in.) | Vessel (in.) | Size (in.) | Support (in.) | Basket (in.) | ||||||||||

| 2 | 2.375 | 8.625 | 5 | 5 1/2 | 9 | 18 1/2 | 18 | 9 1/2 | 0.218 | 0.322 | No | 3/4 | 1/4 | 1/4 | 1000% | 2 |

| 3 | 3.5 | 8.625 | 5 | 5 1/2 | 9 | 18 1/2 | 21 | 9 1/2 | 0.216 | 0.5 | No | 3/4 | 1/4 | 1/4 | 500% | 3 |

| 4 | 4.5 | 10.75 | 6 | 8 | 11 | 24 | 23 1/2 | 13 | 0.237 | 0.5 | No | 3/4 | 1/4 | 1/4 | 500% | 4 |

| 6 | 6.625 | 12.75 | 8 | 10 | 12 3/8 | 27 7/8 | 27 | 15 1/2 | 0.28 | 0.5 | No | 3/4 | 1/4 | 1/4 | 400% | 6 |

| 8 | 8.625 | 16 | 10 | 13 | 15 | 35 | 32 | 20 | 0.5 | 0.656 | No | 1 | 1/4 | 1/4 | 350% | 8 |

| 10 | 10.75 | 18 | 12 | 16 | 17 3/8 | 40 7/8 | 36 | 23 1/2 | 0.5 | 0.656 | No | 1 | 1/4 | 1/4 | 350% | 10 |

| 12 | 12.75 | 20 | 14 | 19 | 19 5/8 | 46 5/8 | 40 | 27 | 0.5 | 0.812 | No | 2 | 1/4 | 1/4 | 350% | 12 |

600 PSIG

| Sizes, Dimensions and Weights | ||||||||||||||||

| Nominal Line Size (in.) | Nozzle Size (in.) | Vessel Size (in.) | Basket Size | A (in.) | B (in.) | C (in.) | D (in.) | Wall Thickness | Pads Req'd | Drian Ring Thickness | Ratio of Inlet ID Area to Basket Open Area | Nominal Line Size (in.) | ||||

| Diam. (in.) | Avg. Ht (in.) | Nozzle (in.) | Vessel (in.) | Size (in.) | Support (in.) | Basket (in.) | ||||||||||

| 2 | 2.375 | 8.625 | 5 | 5 1/2 | 9 | 18 1/2 | 21 | 9 1/2 | 0.218 | 0.593 | No | 3/4 | 1/4 | 1/4 | 1000% | 2 |

| 3 | 3.5 | 8.625 | 5 | 5 1/2 | 9 | 18 1/2 | 23 | 9 1/2 | 0.3 | 0.593 | No | 3/4 | 1/4 | 1/4 | 500% | 3 |

| 4 | 4.5 | 10.75 | 6 | 8 | 11 | 24 | 26 1/2 | 13 | 0.337 | 0.5 | Yes | 3/4 | 1/4 | 1/4 | 500% | 4 |

| 6 | 6.625 | 12.75 | 8 | 10 | 12 3/8 | 27 7/8 | 31 1/2 | 15 1/2 | 0.432 | 0.5 | Yes | 3/4 | 1/4 | 1/4 | 400% | 6 |

| 8 | 8.625 | 16 | 10 | 13 | 15 | 35 | 38 | 20 | 0.5 | 0.656 | Yes | 1 | 1/4 | 1/4 | 350% | 8 |

| 10 | 10.75 | 18 | 12 | 16 | 17 3/8 | 40 7/8 | 42 1/2 | 23 1/2 | 0.5 | 0.656 | Yes | 1 | 1/4 | 1/4 | 350% | 10 |

| 12 | 12.75 | 20 | 14 | 19 | 19 5/8 | 46 5/8 | 45 1/2 | 27 | 0.687 | 0.812 | Yes | 2 | 1/4 | 1/4 | 350% | 12 |

| NOMINAL PIPE SIZE | ID | 150# ASA | 300# ASA | 600# ASA | 900# ASA |

| 3/4 | 3/4 | 2 1/8 | 2 1/2 | 2 1/2 | 2 5/8 |

| 1 | 1 | 2 1/2 | 2 3/4 | 2 3/4 | 3 |

| 1 1/2 | 1 1/2 | 3 1/4 | 3 5/8 | 3 5/8 | 3 3/4 |

| 2 | 2 | 4 | 4 1/4 | 4 1/4 | 5 1/2 |

| 2 1/2 | 2 1/2 | 4 3/4 | 5 | 5 | 6 3/8 |

| 3 | 3 | 5 1/4 | 5 3/4 | 5 3/4 | 6 1/2 |

| 4 | 4 | 6 3/4 | 7 | 7 1/2 | 8 |

| 5 | 5 | 7 5/8 | 8 3/8 | 9 3/8 | 9 5/8 |

| 6 | 6 | 8 5/8 | 9 3/4 | 10 3/8 | 11 1/4 |

| 8 | 8 | 10 7/8 | 12 | 12 1/2 | 14 |

| 10 | 10 | 13 1/4 | 14 1/8 | 15 5/8 | 17 |

| 12 | 12 | 16 | 16 1/2 | 17 7/8 | 19 1/2 |

| 14 | 13 1/4 | 17 5/8 | 19 | 19 1/4 | 20 3/8 |

| 16 | 15 1/4 | 20 1/8 | 21 1/8 | 22 1/8 | 22 1/2 |

| 18 | 17 1/4 | 21 1/2 | 23 5/8 | 24 | 25 |

| 20 | 19 1/4 | 23 3/4 | 25 5/8 | 26 3/4 | 27 3/8 |

| 24 | 23 1/4 | 28 1/8 | 30 3/8 | 31 | 32 7/8 |